Best Electric vehicle Heatsink Manufacturer and Dealers in Delhi NCR | BL Enterprises

2025-09-06The rise of electric vehicles (EVs) in India is no longer a distant vision-it's happening now. From compact city commuters to electric buses and bikes, the transition to clean mobility is reshaping the automotive landscape. But behind every efficient EV is a hidden hero that ensures its performance, safety, and longevity: the heatsink.

In the electric vehicle ecosystem, heatsinks play a crucial role in managing thermal performance. As power electronics like motor controllers, inverters, and battery systems work harder and longer, they generate heat-lots of it. If not controlled properly, that heat can reduce efficiency, degrade components, or worse, lead to system failure.

This is where high-quality, precision-engineered electric vehicle heatsinks come in-and why choosing the right manufacturer and dealer in Delhi NCR matters more than ever.

Why Heatsinks Are Vital in Electric Vehicles

1. Thermal Management for Safety and Performance

Electric vehicles operate through high-power electrical systems, and any fluctuation in temperature can severely impact performance. Heatsinks absorb and dissipate this excess heat, keeping components within optimal temperature ranges. This helps prevent overheating, enhances efficiency, and ensures safe operation.

2. Improved Lifespan of Electronic Components

Consistent high temperatures shorten the lifespan of EV parts such as IGBTs, MOSFETs, and lithium-ion batteries. By maintaining stable temperatures, heatsinks help extend component durability-making the vehicle more reliable over time.

3. Increased Energy Efficiency

Heat is energy lost. With proper heat dissipation, electric vehicles can function more efficiently, consuming less power to perform the same tasks. That translates into better mileage, faster charging, and improved user experience.

Delhi NCR: A Hotspot for EV Component Manufacturing

With India pushing aggressively toward EV adoption, the Delhi NCR region has emerged as a hub for electric vehicle infrastructure and component manufacturing. The region’s proximity to automotive OEMs, skilled labor, advanced R&D centers, and government incentives makes it the perfect ground for heatsink manufacturers and dealers.

If you are an OEM, Tier-1 supplier, startup, or fleet operator looking for high-performance heatsinks, Delhi NCR offers access to top-tier suppliers who understand the evolving needs of EV engineering.

What to Look for in an EV Heatsink Manufacturer or Dealer

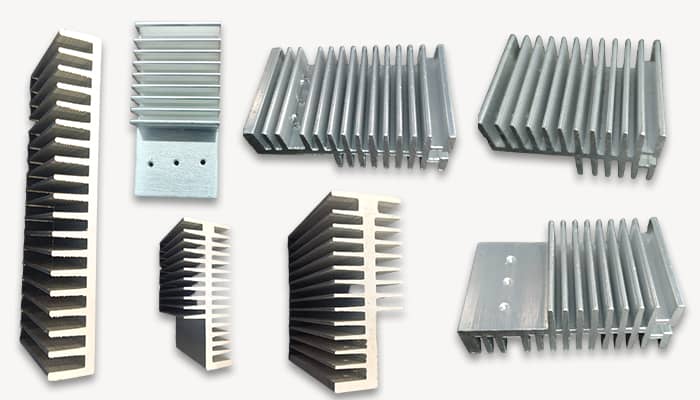

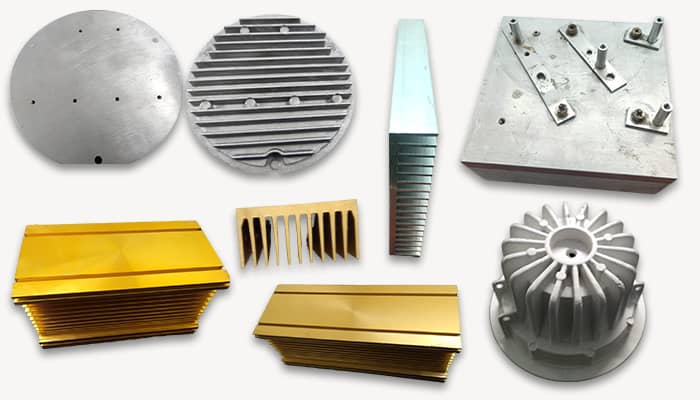

- Material Expertise: Ensure use of high-grade aluminium alloys with customization options in design, thickness, and coating.

- Manufacturing Capabilities: Look for extrusion, CNC machining, die-casting, and surface treatment capabilities.

- Industry Certifications: ISO 9001, IATF 16949, and RoHS compliance are key indicators of quality and reliability.

- Customization & Design Support: Choose suppliers that offer simulations, thermal testing, and prototyping services.

- Prompt Delivery & Inventory: Go for partners who can deliver consistently and support scaling as your needs grow.

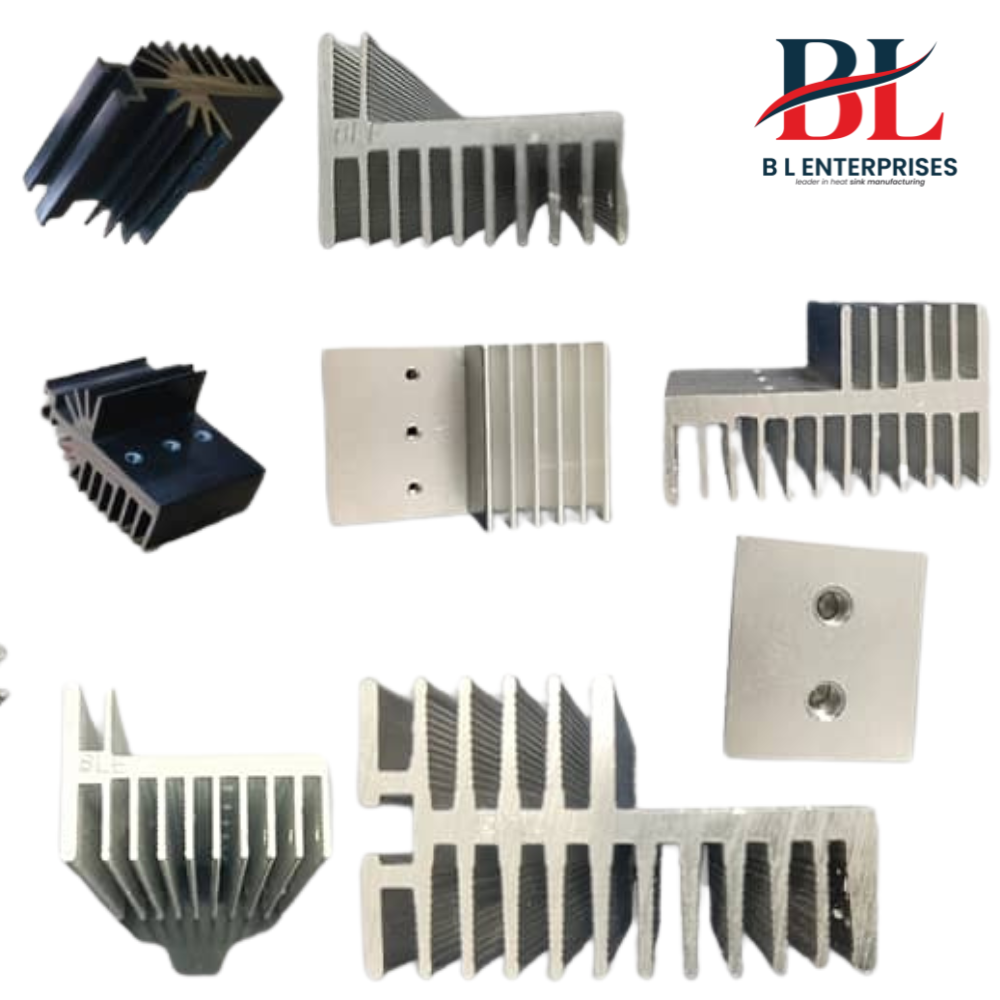

The Best in the Business – BL Enterprises

Among the standout names in the region, BL Enterprises has emerged as a trusted and experienced manufacturer and dealer of electric vehicle heatsinks. Known for its deep domain expertise, state-of-the-art facilities, and a strong focus on thermal management solutions, the company has supported numerous EV startups and OEMs across India.

From high-precision aluminium heatsinks for controllers and inverters to passive and active cooling systems, BL Enterprises delivers quality solutions tailored for electric mobility. Their commitment to innovation and customer satisfaction sets them apart as a preferred partner in the rapidly growing EV sector.

Key Applications of Heatsinks in Electric Vehicles

- Battery Management Systems (BMS): Keeps battery modules at ideal operating temperatures to prevent thermal runaway.

- Motor Controllers & Inverters: Helps dissipate heat generated during power conversion and regulation.

- DC-DC Converters & Onboard Chargers: Critical components that benefit from thermal regulation to enhance efficiency.

- LED Headlights and Displays: Smaller heatsinks are used to prevent LED degradation due to overheating.

The Road Ahead: Innovation in Heatsink Technology

- Liquid-Cooled Heatsinks: Combining conduction and convection to handle higher thermal loads.

- Graphene and Advanced Composites: Offering superior heat conductivity and weight reduction.

- 3D Printed Heatsinks: Enabling fast prototyping and complex geometries.

- Integrated Thermal Modules: Combining fans, heat pipes, and TIMs for all-in-one thermal solutions.

Delhi NCR-based manufacturers are well-positioned to lead these innovations thanks to increasing R&D investments and clean-tech focus.

Why Local Sourcing Matters

- Faster Lead Times: Reduced transportation and quicker fulfillment.

- Lower Costs: Save on logistics, customs, and duties.

- Better Communication: Easier collaboration for design, testing, and feedback.

- Local Support: On-site service and technical assistance.

In a rapidly changing industry like EVs, having a responsive and reliable local partner makes all the difference.

Conclusion

As India’s EV ecosystem matures, the role of high-quality heatsinks becomes increasingly critical to vehicle performance, safety, and customer satisfaction. For businesses and manufacturers operating in Delhi NCR, working with a trusted and capable heatsink supplier ensures you're not just keeping up-but leading the charge.

Whether you're designing a new electric scooter, building electric buses, or supplying to major OEMs, finding the right heatsink solution is key to your success. And with companies like BL Enterprises offering world-class solutions, the future of EV thermal management in India looks bright, efficient, and unstoppable.

Frequently Asked Questions (FAQs)

1. What is the role of heatsinks in electric vehicles?

Heatsinks dissipate heat generated by high-power electronics such as inverters, controllers, and battery systems, ensuring safe and efficient operation.

2. Why choose a local EV heatsink manufacturer in Delhi NCR?

Local manufacturers offer quicker turnaround times, reduced logistics costs, and better on-ground support for design and post-sales service.

3. Can heatsinks be customized for specific EV applications?

Yes, manufacturers provide tailored solutions based on the thermal needs, component size, and vehicle type, including design simulations and prototyping.

4. Are aluminium heatsinks the best choice for EVs?

Aluminium is preferred due to its excellent thermal conductivity, lightweight nature, and ease of manufacturing, making it ideal for EV applications.

5. What are the future trends in EV heatsink technology?

Trends include liquid cooling, use of advanced materials like graphene, 3D printed heatsinks, and integrated thermal management modules for higher efficiency.